|

Batteries come in a lot of different varieties, and many

years of work at universities, government labs, industrial workshops and

inventor's basements have been put into investigating thousands of different

chemistries. The most common are carbon-zinc, alkaline, lead acid, nickel metal

hydride, nickel cadmium, lithium iron phosphate and lithium ion. But there are

many other commercially available battery chemistries, each with their own

advantages and disadvantages. Below we discuss different of the battery designs

currently used, some of the chemistry involved, and advantages and

disadvantages of each design. We have also included some useful definitions and

a list of parameters to guide you in matching your battery requirements to a

specific battery design.

- More Technical

Resources on the PowerStream Web Site

Table of Contents

- Anode: The electrode where oxidation (loss of

electrons) takes place. The anode of a battery is the negative electrode when

discharging, and when charging it is connected to the negative electrode of the

charger. So when the anode is charging it technically receives electrons,

making it the cathode, but no-one ever makes this distinction due to the

confusion it can cause.

- Amps: Also known as Amperes. This is the

rate at which electrons flow in a wire. The units are coulombs per second, or

since an electron has a charge of 1.602 x 10-19 coulombs, an amp is

6.24 x 10+18 electrons per second. Think of marbles rolling through

a tube. If 6.24 x 10+18 pass by in 1 second you would have an amp of

marbles.

- Amp hours: Also known as ampere hours.

This a measure of the amount of charge stored or used. For example if you had

an amp of marbles flowing out of your tube into a bucket for an hour, you would

have one amp-hour of marbles in the bucket ( 6.24 x 10+18 times 3600

seconds = 2.2 x 10+22 marbles. A 1 amp hour battery contains enough

charge to supply 1 amp for 1 hour, if you discharge at a constant rate of

current. But note that usually if you discharge faster than the rate at which

the the amp hours were specified you will get fewer amp-hours out, see the

definition of Peukart Effect below.

- You may notice that amp-hours and coulombs measure

the same quantity-charge. One amp-hour is 3600 coulombs, but amp hours are

easier to use in battery design. So remember, amps are flow ( "this motor

requires 2 amps to run at 1800 rpm.") Amp hours measure capacity, quantity, or

amount of charge ("this 100 amp-hour battery will supply 2 amps for 50 hours

before needingrecharge." Amp-hours are amps times hours, not amps

divided by hours.

So Amp-Hours, (AH), or milliamp-Hours (mAH) is a

measure of the size of the battery a 10 mAH battery has half the capacity of a

20 mAH battery, even though they may be in the same physical package.

- Batteries: Two or more electrochemical cells,

electrically interconnected, each of which contains two electrodes and an

electrolyte. The redox (oxidation-reduction) reactions that occur at these

electrodes convert electrochemical energy into electrical energy. In everyday

usage, 'battery' is also used to refer to a single cell, but technically it is

a combination of two or more.

- C:C represents the capacity of a battery divided

by 1 hour, its units are amps. It represents a 1 hour discharge rate using the

nominal capacity of the battery. So a discharge rate of 10C for a 5AH battery

would be 50 amps. A discharge rate of C/10 would be 0.5 amps. The concept of

"C" is also used for charge currents, since both charge and discharge

properties are proportional to the capacity of the battery, so a 5C charge rate

for a 5 AH battery would be 25 amps.

- Capacity: The total quantity of electricity or

total ampere-hours available from a fully charged cell or battery.

- Cathode: The electrode where reduction (gain of

electrons) takes place. The same confusion applies when charging as the anode,

but the cathode remains the positive side of the battery to avoid

confusion.

- Charge: The conversion of electrical energy,

provided in the form of current from an external source, into chemical energy

stored at the electrodes of a cell or battery.

- Discharge: The conversion of the chemical energy

of a cell into electrical energy, which can then be used to supply power to a

system.

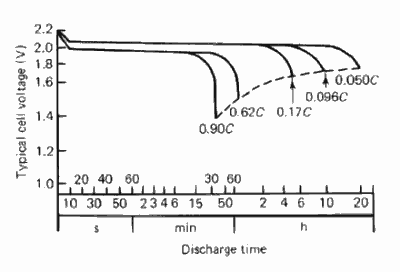

- Discharge curve: A plot of cell voltage over

time into the discharge, at a constant temperature and constant current

discharge rate.

Each curve in this graph represents cell

performance at a different discharge rate. The farther right the curve ends,

the lower the discharge rate (Crompton 31.4).

- Dry cell: A

Leclanché cell, so called because of its non-fluid electrolyte (to

prevent spillage). This is achieved by adding an inert metal oxide so that the

electrolyte forms a gel or paste.

- Efficiency: For a secondary cell, the ratio of

the output on discharge to the input required to restore it to its initial

state of charge under specified conditions. Can be measured as ampere-hour,

voltage, or watt-hour efficiency.

- Electrolyte: The chemistry of a battery requires

a medium that provides the ion transport mechanism between the positive and

negative electrodes of a cell. This is often a water solution, but in lithium

batteries it consists of organic solvents with dissolved salts.

- Energy density (specific energy): These two

terms are often used interchangeably. Energy density refers mainly to

the ratio of a battery's available energy to its volume (watt hour/liter).

Specific energy refers to the ratio of energy to mass (watt hour/kg).

The energy is determined by the charge that can be stored and the cell voltage

(E=qV).

- Fuel cell: A cell in which one or both of the

reactants are not permanently contained in the cell, but are continuously

supplied from a source external to the cell and the reaction products

continuously removed. Unlike the metal anodes typically used in batteries, the

fuels in a fuel cell are usually gas or liquid, with oxygen as the oxidant. The

hydrogen/oxygen fuel cell is the most common. In this fuel cell, hydrogen is

oxidized at the anode:

| half-reaction |

V versus SHE |

| 2H2 > 4H+ +

4e- |

0 |

| 4H+ + O2 +

4e- > 2H2O |

1.2 |

Hydrogen/oxygen fuel cell systems

work well in space travel applications because of their high efficiency, high

power-to-weight and volume ratios, and usable reaction product (water). They

can function for many months as long as fuel is supplied and therefore the

energy density cannot be measured.

- Half-reaction: Refers to the chemical processes

occurring at each electrode. The potential of the two half-reactions add to

give us the overall cell potential. We can see this in the zinc mercury cell,

for example:

| Location |

Reaction |

Potential |

| Anode |

Zn + 2OH- > Zn(OH)2 +

2e- |

1.25 V |

| Cathode |

HgO +H2O + 2e- > Hg +

2OH- |

0.098 V |

| Overall |

Zn + HgO + H2O >

Zn(OH)2 + Hg |

1.35 V |

- Polarization: The voltage drop in a cell during

discharge due to the flow of an electrical current. The cell's internal

resistance increases with the buildup of a product of oxidation or a reduction

of an electrode, preventing further reaction.

- Power: Defined by voltage (V) and current (I),

P=VI.

Since V=IR, P=I2R and P=V2/R

Power also can be described by energy emitted per unit

of time: P=E/t.

Thus E=VIt=qV.

- Power density (specific power): Power

density is the ratio of the power available from a battery to its volume

(watts/liter). Specific power generally refers to the ratio of power to

mass (watts/kg). Comparison of power to cell mass is more common.

- Primary cells: A cell that is not designed for

recharging and is discarded once it has produced all its electrical

energy.

- Prismatic: Just a word to say that the cells are

not cylindrical, as nature intended battery cells to be, but fit nicely into a

parallelepiped, rectangular or any other such flattened shape.

- Peukart Effect: When a battery is discharged

extremely quickly it will have less capacity than expected. This is the Peukart

effect, which is very strong for lead acid batteries and many primary cells,

but much less so for nickel cadmium, NiMH and lithium batteries. Peukert's

equation is In · t = C, where I is the discharge rate, t is

the discharge time and C is the capacity. The exponent "n" depends on the

battery chemistry and the temperature. A log-log plot of discharge time versus

discharge load will have a slope of "n"

- Reserve cell: A primary cell that may be kept

inactive and which is activated by adding an electrolyte or electrode, or

melting an electrolyte which is normally in a solid state.

- Secondary cells: A cell capable of repeated use.

Its charge may be fully restored by passing an electric current through the

cell in the opposite direction to that of discharge, thus reversing the redox

reactions.

No one battery design is perfect for every application.

Choosing one requires compromise. That's why it's important to prioritize your

list of requirements. Decide which ones you absolutely must have and which you

can compromise on. Here are some of the parameters to consider:

- Voltage: Normal voltage during discharge,

maximum and minimum permissible voltages, discharge curve profile. Note that

secondary cells are characterized by their average voltage during a full

discharge, whereas primary cells are characterized by their peak voltage. Thus

an alkaline cells is rated at 1.5V, though its average voltage during discharge

is 1.2V. A NiMH cell is rated at 1.2 volts, but its discharge range is 1.4 to 1

volt.

- Duty cycle: Conditions the battery experiences

during use. Type of discharge and current drain, e.g.., continuous,

intermittent, continuous with pulses, etc. A 50% duty cycle means that the cell

is off for half the cycle, and on for the other half of the cycle.

- Temperature: In storage and in use. Temperatures

that are too high or too low can greatly reduce battery capacity.

- Shelf life: How rapidly the cell loses potential

while unused.

- Service life: Defined either in calendar time

or, for secondary cells, possible number of discharge/charge cycles, depending

on the battery application. Service life depends on battery design and

operational conditions, i.e., the stress put on a battery. For stationary and

motive power application, the end of service life is defined as the point at

which a battery's capacity drops to 80% of its original capacity. Exceptions

would include car batteries where the service life ends when the capacity falls

below 60%.

- Physical restrictions: These include dimensions,

weight, terminals, etc.

- Maintenance and resupply: Ease of battery

acquisition, replacement, charging facilities, disposal.

- Safety and reliability: Failure rates, freedom

from outgassing or leakage; use of toxic components; operation under hazardous

conditions; environmentally safe

- Cost: Initial cost, operating cost, use of

expensive materials

- Internal resistance: Batteries capable of a

high-rate discharge must have a low internal resistance.

- Specific energy: As discussed in the definition

section, this is a measurement of possible stored energy per kilogram of mass.

This number is purely theoretical as it does not take into account the mass of

inactive materials, nor the variation in chemical reactions.

- Specific power: Also defined in the definitions

section, a P=E/t, so the specific power is discussed at a specific discharge

rate. It is possible for batteries with a high specific energy to have a low

power density if they experience large voltage drops at high discharge rates.

Specific power and specific energy can be compared in a Ragone plot .

- Unusual requirements: Very long-term or

extreme-temperature storage; very low failure rate; no voltage delay, etc.

Of course the ideal battery would perform well in all

these areas with a long shelf and service life, high specific energy and

specific power, low initial and maintenance costs, low environmental impact,

and good performance in a variety of conditions (temperatures, duty cycles,

etc.). When you find one that meets all these requirements, let us know! In the

meantime, we have to make do with batteries that work very well in specific

applications.

Primary Batteries

Leclanché

Cells(zinc carbon or dry

cell)

Anode: Zinc

Cathode: Manganese Dioxide (MnO2)

Electrolyte: Ammonium chloride or zinc chloride

dissolved in water

Applications: Flashlights, toys, moderate drain

use

The basic design of the Leclanché cell has been

around since the 1860s, and until World War II, was the only one in wide use.

It is still the most commonly used of all primary battery designs because of

its low cost, availability, and applicability in various situations. However,

because the Leclanché cell must be discharged intermittently for best

capacity, much of battery research in the last three decades has focused on

zinc-chloride cell systems, which have been found to perform better than the

Leclanché under heavier drain.

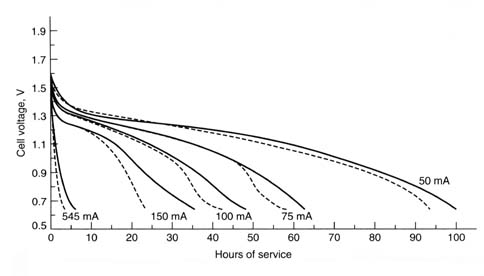

This figure shows typical discharge curves for

general-purpose Leclanché zinc chloride D-size cells discharge 2 H/day

at 20º C. Solid line—zinc chloride; broken

line—Leclanché (Linden 8.18). The zinc-chloride cell has a

higher service life and voltage than the Leclanché (at both higher and

lower discharge rates).

In an ordinary Leclanché cell the electrolyte

consists (in percent of atomic weight) of 26% NH4Cl (ammonium

chloride), 8.8% ZnCl2 (zinc chloride), and 65.2% water. The overall

cell reaction can be expressed:

Zn + 2MnO2 +2NH4Cl —> 2MnOOH

+ Zn(NH3)2Cl2 E=1.26

The electrolyte in a typical zinc chloride cell consists

of 15-40% ZnCl2 and 60-85% water, sometimes with a small amount of

NH4Cl for optimal performance. The overall cell reaction of the zinc

chloride as the electrolyte can be expressed:

Zn + 2MnO2 + 2H2O + ZnCl2

—> 2MnOOH + 2Zn(OH)Cl

MnO2, is only slightly conductive, so graphite

is added to improve conductivity. The cell voltage increases by using

synthetically produced manganese dioxide instead of that found naturally

(called pyrolusite). This does drive the cost up a bit, but it is still

inexpensive and environmentally friendly, making it a popular cathode.

These cells are the cheapest ones in wide use, but they

also have the lowest energy density and perform poorly under high-current

applications. Still, the zinc carbon design is reliable and more than adequate

for many everyday applications.

Anode: Zinc powder

Cathode: Manganese dioxide (MnO2)

powder

Electrolyte: Potassium hydroxide (KOH)

Applications: Radios, toys, photo-flash

applications, watches, high-drain applications

This cell design gets its name from its use of alkaline

aqueous solutions as electrolytes. Alkaline battery chemistry was first

introduced in the early ’60s. The alkaline cell has grown in popularity,

becoming the zinc-carbon cell's greatest competitor. Alkaline cells have many

acknowledged advantages over zinc-carbon, including a higher energy density,

longer shelf life, superior leakage resistance, better performance in both

continuous and intermittent duty cycles, and lower internal resistance, which

allows it to operate at high discharge rates over a wider temperature

range.

Zinc in a powdered form increases the surface area of the

anode, allowing more particle interaction. This lowers the internal resistance

and increases the power density. The cathode, MnO2, is synthetically

produced because of its superiority to naturally occurring MnO2.

This increases the energy density. Just as in the zinc carbon cell, graphite is

added to the cathode to increase conductivity. The electrolyte, KOH, allows

high ionic conductivity. Zinc oxide is often added to slow down corrosion of

the zinc anode. A cellulose derivative is thrown in as well as a gelling agent.

These materials make the alkaline cell more expensive than the zinc-carbon, but

its improved performance makes it more cost effective, especially in high drain

situations where the alkaline cell's energy density is much higher.

The half-reactions are:

Zn + 2 OH- —> ZnO + H2O + 2

e-

2 MnO2 + H2O + 2 e-

—>Mn2O3 + 2 OH-

The overall reaction is:

Zn + 2MnO2 —> ZnO +

Mn2O3 E=1.5 V

There are other cell designs that fit into the alkaline

cell category, including the mercury oxide, silver oxide, and zinc air cells.

Mercury and silver give even higher energy densities, but cost a lot more and

are being phased out through government regulations because of their high

toxicity as heavy metals. The mercury oxide, silver oxide, and zinc air (which

is being developed for electronic vehicles) are all discussed below.

Mercury Oxide

Cells

Anode: Zinc (or cadmium)

Cathode: Mercuric Oxide (HgO)

Electrolyte: Potassium hydroxide

Applications: Small electronic equipment, hearing

aids, photography, alarm systems, emergency beacons, detonators, radio

microphones

This is an obsolete technology. Most if not all of the

manufacture of these cells has been stopped by government regulators. Mercury

batteries come in two main varieties: zinc/mercuric oxide and cadmium/mercuric

oxide. The zinc/mercuric oxide system has high volumetric specific energy (400

Wh/L), long storage life, and stable voltage. The cadmium/mercuric oxide system

has good high temperature and good low temperature (-55 C to +80 C, some

designs to +180 C) and has very low gas evolution.

| Basic Cell Reaction |

Voltage |

Electrochemical

Efficiency |

| Zn + HgO = ZnO + Hg |

1.35 V |

820 mAH/g(Zn), 250 mAH/g(Hg) |

| Cd + HgO + H2O = Cd(OH2) + Hg |

0.91 V |

480 mAH/g(Cd) |

The electrolytes used in mercury

cells are sodium and/or potassium hydroxide solutions, making these alkaline

cells. These cells are not rechargeable.

Zinc/Air

Cells

Zinc/Air

Cells

Anode: Amalgamated zinc powder and electrolyte

Cathode: Oxygen (O2)

Electrolyte: Potassium hydroxide (KOH)

Applications: Hearing aids, pagers, electric

vehicles

The zinc air cell fits into the alkaline cell category

because of its electrolyte. It also acts as a partial fuel cell because it uses

the O2 from air as the cathode. This cell is interesting technology,

even aside from the question "how do you use air for an electrode?" Actually,

oxygen is let in to the cathode through a hole in the battery and is reduced on

a carbon surface.

A number of battery chemistries involve a metal oxide and

zinc. The metal oxide reduces, the zinc becomes oxidized, and electric current

results. A familiar example is the old mercury oxide/zinc batteries used for

hearing aids. If you leave out the metal oxide you could double the capacity

per unit volume (roughly), but where would you get the oxygen? Right!

First let's look at the electrochemical reactions and find

that the open cell voltage should be 1.65 volts:

| Location |

Half Cell reactions |

Voltage |

| Anode |

Zn2+ + 2OH- —>

Zn(OH)2 |

1.25 |

| Cathode |

1/2 O2 + H2O + 2e —>

2 OH- |

0.4 |

| Overall |

2Zn +O2 +2H2O —>

2Zn(OH)2 |

1.65 |

The electrolyte is an alkali hydroxide in 20-40% weight

solution with water. One disadvantage is that since these hydroxides are

hygroscopic, they will pick up or lose water from the air depending on the

humidity. Both too little and too much humidity reduces the life of the cell.

Selective membranes can help. Oxygen from the air dissolves in the electrolyte

through a porous, hydrophobic electrode—a carbon-polymer or metal-polymer

composite.

Since there is no need to carry around the cathode, the

energy density of these batteries can be quite high, between 220–300 Wh/kg

(compared to 99–123 Wh/kg with a HgO cathode), although the power density

remains low. However, the use of potassium or sodium hydroxides as the

electrolyte is a problem, since these can react with carbon dioxide in the air

to form alkali carbonates. For this reason large zinc air batteries usually

contain a higher volume of CO2 absorbing material (calcium oxide

flake) than battery components. This can cancel out the huge increase in energy

density gained by using the air electrode.

This cell has the additional benefits of being

environmentally friendly at a relatively low cost.

These batteries can last indefinitely before they are

activated by exposing them to air, after which they have a short shelf life.

For this reason (as well as the high energy density) most zinc-air batteries

are used in hearing aids. There is a company promoting them for use in electric

vehicles also because they are environmentally friendly and cost relatively

little. The idea is to have refueling stations where the zinc oxide waste can

be replaced by fresh zinc pellets.

Aluminum Air

Cells

Although, to our way of thinking, the metal/air batteries

are strictly primary, cells have been designed to have the metal replaceable.

These are called mechanically rechargeable batteries. Aluminum/air is an

example of such a cell. Aluminum is attractive for such cells because it is

highly reactive, the aluminum oxide protective layer is dissolved by hydroxide

electrolytes, and it has a nice, high voltage. The overall chemical reaction

is:

| Location |

Half Cell reactions |

Voltage |

| Anode |

Al + 4 OH-—>

Al(OH)4- + 3e |

-2.35 |

| Cathode |

3/4 O2 + 3/2 H2O + 3e—>

3OH- |

0.40 |

| Overall |

Al + 3/2 HO + 3/4 O2 —>

Al(OH)3 |

2.75 V |

As I mentioned above, alkali (chiefly potassium hydroxide)

electrolytes are used, but so also are neutral salt solutions. The alkali cell

has some problem with the air electrode, because the hydroxide ion makes a gel

in the porous electrode, polarizing it. The typical aluminum hydroxide gel is a

problem on either electrode because it sucks up a lot of water. Using a

concentrated caustic solution prevents this, but is very reactive with the

aluminum electrode, producing hydrogen gas. Another way to prevent the gel

formation is to seed the electrolyte with aluminum trihydroxide crystals. These

act to convert the aluminum hydroxide to aluminum trihydroxide as the crystals

grow. To prevent hydrogen gas evolution tin and zinc have been used as

corrosion inhibitors. A number of additives are used to control the reactions.

A disadvantage of the alkaline electrolyte is that it reacts with atmospheric

carbon dioxide.

Aluminum / air cells have also been made for marine

applications. These are "rechargeable" by replacing the seawater electrolyte

until the aluminum is exhausted, then replacing the aluminum. Some cells that

are open to seawater have also been researched. Since salt water solutions tend

to passivate the aluminum, pumping the electrolyte back and forth along the

cell surface has been successful. For those cells that don't need to use ocean

water, an electrolyte of KCL and KF solutions is used.

Air electrodes of Teflon-bonded carbon are used without a

catalyst.

v v

Lithium

Cells

Applications: Pacemakers, defibrillators, watches,

meters, cameras, calculators, portable, low-power use

Lithium battery chemistry comprise a number of cell

designs that use lithium as the anode. Lithium is gaining a lot of popularity

as an anode for a number of reasons. In this comparison of anode materials, we

can see some reasons why:

| Anode |

Atomic

mass (g) |

Standard

potential (V) |

Density

g/cm3 |

Melting

point ºC |

Electrochemical

Equivalence

(Ah/g) |

| Li |

6.94 |

3.05 |

0.54 |

180 |

3.86 |

| Na |

23.0 |

2.7 |

0.97 |

97.8 |

1.16 |

| Mg |

24.3 |

2.4 |

1.74 |

650 |

2.20 |

| Al |

26.9 |

1.7 |

2.7 |

659 |

2.98 |

| Ca |

40.1 |

2.87 |

1.54 |

851 |

1.34 |

| Fe |

55.8 |

0.44 |

7.85 |

1528 |

0.96 |

| Zn |

65.4 |

0.76 |

7.1 |

419 |

0.82 |

| Cd |

112 |

0.40 |

8.65 |

321 |

0.48 |

| Pb |

207 |

0.13 |

11.3 |

327 |

0.26 |

Note that lithium, the lightest of the metals, also has

the highest standard potential of all the metals, at over 3 V. Some of the

lithium cell designs have a voltage of nearly 4 V. This means that lithium has

the highest energy density. Many different lithium cells exist because of its

stability and low reactivity with a number of cathodes and non-aqueous

electrolytes. The most common electrolytes are organic liquids with the notable

exceptions of SOCl2 (thionyl chloride) and

SO2Cl2 (sulfuryl chloride). Solutes are added to the

electrolytes to increase conductivity.

Lithium cells have only recently become commercially

viable because lithium reacts violently with water, as well as nitrogen in air.

This requires sealed cells. High-rate lithium cells can build up pressure if

they short circuit and cause the temperature and pressure to rise. Thus, the

cell design needs to include weak points, or safety vents, which rupture at a

certain pressure to prevent explosion.

Lithium cells can be grouped into three general

categories: liquid cathode, solid cathode, and solid electrolyte. Let's look at

some specific lithium cell designs within the context of these three

categories.

v v

Liquid cathode lithium cells:

These cells tend to offer higher discharge rates because

the reactions occur at the cathode surface. In a solid cathode, the reactions

take longer because the lithium ions must enter into the cathode for discharge

to occur. The direct contact between the liquid cathode and the lithium forms a

film over the lithium, called the solid electrolyte interface (SEI). This

prevents further chemical reaction when not in use, thus preserving the cell's

shelf life. One drawback, though, is that if the film is too thick, it causes

an initial voltage delay. Usually, water contamination is the reason for the

thicker film, so quality control is important.

LiSO2

Lithium–Sulfur Dioxide LiSO2

Lithium–Sulfur Dioxide

This cell performs very well in high current applications

as well as in low temperatures. It has an open voltage of almost 3 V and a

typical energy density of 240–280 Wh/kg. It uses a cathode of porous

carbon with sulfur dioxide taking part in the reaction at the cathode. The

electrolyte consists of an acetonitrile solvent and a lithium bromide solute.

Polypropylene acts as a separator. Lithium and sulfur dioxide combine to form

lithium dithionite:

2Li + 2SO2 —>

Li2S2O4

These cells are mainly used in military applications for

communication because of high cost and safety concerns in high-discharge

situations, i.e., pressure buildup and overheating.

LiSOCl2 Lithium Thionyl Chloride LiSOCl2 Lithium Thionyl Chloride

This cell consists of a high-surface area carbon cathode,

a non-woven glass separator, and thionyl chloride, which doubles as the

electrolyte solvent and the active cathode material. Lithium aluminum chloride

(LiAlCl4) acts as the electrolyte salt.

The materials react as follows:

| Location |

Reaction |

| Anode |

Li —> Li+ + e- |

| Cathode |

4Li+ + 4e- +

2SOCl2 —> 4LiCl + SO2 + S |

| Overall |

4Li + 2SOCl2 —> 4LiCl +

SO2 + S |

During discharge the anode gives off lithium ions. On the

carbon surface, the thionyl chloride reduces to chloride ions, sulfur dioxide,

and sulfur. The lithium and chloride ions then form lithium chloride. Once the

lithium chloride has deposited at a site on the carbon surface, that site is

rendered inactive. The sulfur and sulfur dioxide dissolve in the electrolyte,

but at higher-rate discharges SO2 will increase the cell

pressure.

This system has a very high energy density (about 500

Wh/kg) and an operating voltage of 3.3–3.5 V. The cell is generally a

low-pressure system

In high-rate discharge, the voltage delay is more

pronounced and the pressure increases as mentioned before. Low-rate cells are

used commercially for small electronics and memory backup. High-rate cells are

used mainly for military applications.

Solid cathode lithium cells:

These cells cannot be used in high-drain applications and

don't perform as well as the liquid cathode cells in low temperatures. However,

they don't have the same voltage delay and the cells don't require

pressurization. They are used generally for memory backup, watches, portable

electronic devices, etc.

LiMnO2 LiMnO2

These account for about 80% of all primary lithium cells,

one reason being their low cost. The cathode used is a heat-treated

MnO2 and the electrolyte a mixture of propylene carbonate and

1,2-dimethoyethane. The half reactions are

| Anode |

Li —> Li+ + e |

| Cathode |

MnIVO2 + Li+ + e

—> MnIIIO2(Li+) |

| Overall |

Li + MnIVO2 —>

MnIIIO2(Li+) |

At lower temperatures and in high-rate discharge, the

LiSO2 cell performs much better than the LiMnO2 cell. At

low-rate discharge and higher temperatures, the two cells perform equally well,

but LiMnO2 cell has the advantage because it doesn't require

pressurization.

Li(CF)n

Lithium polycarbon monofluoride Li(CF)n

Lithium polycarbon monofluoride

These cells are used in coin cells for watches and

memory-back up, nuclear missile batteries, the space shuttle safety system, and

other governmental and space applications. The cathode in this cell is carbon

monofluoride, a compound formed through high-temperature intercalation. This is

the process where foreign atoms (in this case fluorine gas) incorporate

themselves into some crystal lattice (graphite powder), with the crystal

lattice atoms retaining their positions relative to one another. This is not a

stoichiometric reaction, so the proportion of fluorine atoms can vary between

0.8 and 1.2, which is why the half-reactions are also not stoichiometric. This

is interesting because it allows a lithium-fluorine reaction, which is probably

the most energetic possible by safely storing the fluorine atoms in a graphite

matrix. This is similar to how lithium ions are stored in lithium ion

batteries. The carbon intercalation makes it safe, but it also reduces the

voltage and lowers the electrical current capability.

A typical electrolyte is lithium tetrafluoroborate

(LiBF4) salt in a solution of propylene carbonate (PC) and

dimethoxyethane (DME).

| Anode |

Li —> Li+ + e |

| Cathode |

CFx + xe —> xC +

xF |

| Overall |

CFx + xLi —>

xLiF+ xC |

Note that one of the reaction products is carbon, which

lowers the resistance of the cell as the battery is discharged. These cells

also have a high voltage (about 3.0 V open voltage) and a high energy density

(around 250 Wh/kg). All this and a 7-year shelf life makes them very suitable

for low- to moderate-drain use, e.g., watches, calculators, and memory

applications.

v v

Solid electrolyte lithium cells:

All commercially manufactured cells that use a solid

electrolyte have a lithium anode. They perform best in low-current applications

and have a very long service life. For this reason, they are used in

pacemakers

LiI2—Lithium iodine cells use solid LiI as their

electrolyte and also produce LiI as the cell discharges. The cathode is

poly-2-vinylpyridine (P2VP) with the following reactions: LiI2—Lithium iodine cells use solid LiI as their

electrolyte and also produce LiI as the cell discharges. The cathode is

poly-2-vinylpyridine (P2VP) with the following reactions:

| Anode |

2Li —> 2Li+ + 2e |

| Cathode |

2Li+ + 2e + P2VP· nI2 —> P2VP· (n–1)I2 + 2LiI |

| Overall |

2Li + P2VP·

nI2 —> P2VP·

(n–1)I2 +2LiI |

LiI is formed in situ by direct reaction of the

electrodes.

Lithium-Iron Cells

The Lithium-Iron

chemistry deserves a separate section because it is one of a handful of lithium

metal systems that have a 1.5 volt output (others are lithium/lead bismuthate,

lithium/bismuth trioxide, lithium/copper oxide, and lithium/copper sulfide).

Recently consumer cells that use the Li/Fe have reached the market, including

the Energizer. These have advantage of having the same voltage as alkaline

batteries with much more energy storage capacity, so they are called "voltage

compatible" lithiums. They are not rechargeable. They have about 2.5 times the

capacity of an alkaline battery of the same size, but only under high current

discharge conditions (digital cameras, flashlights, motor driven toys, etc.).

For small currents they don't have any advantage. Another advantage is the low

self-discharge rate–10 years storage is quoted by the manufacturer. The

discharge reactions are:

| Type |

Reaction |

Nominal Voltage |

Range |

| FeS2 Version |

2 FeS2 + 4 Li —> Fe +

2Li2S |

1.6 Volts |

1.6-1.4 V |

| FeS Version |

FeS + 2Li —> Fe + Li2S |

1.5 Volts |

1.5-1.2 V |

Both Iron sulfide and Iron disulfide are used, the

FeS2 is used in the Energizer. Electrolytes are organic materials such as

propylene carbonate, dioxolane and dimethoxyelthane

Magnesium-Copper Chloride Reserve Cells

The

magnesium-cuprous chloride system is a member of the reserve cell family. It

can't be used as a primary battery because of its high self-discharge rate, but

it has a high discharge rate and power density, so it can be made "dry charged"

and sit forever ready, just add water. The added advantage of being

light-weight has made these practical for portable emergency

batteries.

It works by depositing copper metal out onto the magnesium

anode, just like the old copper-coated nail experiment.

Variations of

this battery use silver chloride, lead chloride, copper iodide, or copper

thiocyanate to react with the magnesium.

The water does not have to be

pure, sea water, tap water, or even bio-derived waste fluids have been used.

The torpedo batteries force seawater through the battery to get up to 460 kW of

power to drive the propeller.

| Type |

Reaction |

Nominal Voltage |

Range |

| Mg CuCl |

Mg + 2 CuCl —> MgCl2+ 2 Cu |

1.6 Volts |

1.5-1.6V |

Secondary batteries

Anode: Sponge metallic lead

Cathode: Lead dioxide (PbO2)

Electrolyte: Dilute mixture of aqueous sulfuric

acid

Applications: Motive power in cars, trucks,

forklifts, construction equipment, recreational water craft, standby/backup

systems

Used mainly for engine batteries, these cells represent

over half of all battery sales. Some advantages are their low cost, long life

cycle, and ability to withstand mistreatment. They also perform well in high

and low temperatures and in high-drain applications. The chemistry lead acid

battery half-cell reactions are:

| half-reaction |

V vs SHE |

| Pb + SO42- —>

PbSO4 + 2e- |

.356 |

| PbO2 + SO42- +

4H+ + 2e- —> PbSO4 +

2H2O |

1.685 |

There are a few problems with this design. If the cell

voltages exceed 2.39 V, the water breaks down into hydrogen and oxygen (this

so-called gassing voltage is temperature dependent, for a chart of the

temperature dependence click here  ). This requires replacing the cell's water. Also, as the

hydrogen and oxygen vent from the cell, too high a concentration of this

mixture will cause an explosion. Another problem arising from this system is

that fumes from the acid or hydroxide solution may have a corrosive effect on

the area surrounding the battery. ). This requires replacing the cell's water. Also, as the

hydrogen and oxygen vent from the cell, too high a concentration of this

mixture will cause an explosion. Another problem arising from this system is

that fumes from the acid or hydroxide solution may have a corrosive effect on

the area surrounding the battery.

These problems are mostly solved by sealed cells, made

commercially available in the 1970s. In the case of lead acid cells, the term

"valve-regulated cells" is more accurate, because they cannot be sealed

completely. If they were, the hydrogen gas would cause the pressure to build up

beyond safe limits. Catalytic gas re-combiners do a great deal to alleviate

this problem. They convert the hydrogen and oxygen back into water, achieving

about 85% efficiency at best. Although this doesn't entirely eliminate the

hydrogen and oxygen gas, the water lost becomes so insignificant that no refill

is needed for the life of the battery. For this reason , these cells are often

referred to as maintenance-free batteries. Also, this cell design prevents

corrosive fumes from escaping.

These cells have a low cycle life, a quick self discharge,

and low energy densities (normally between 30 and 40 Wh/kg). However, with a

nominal voltage of 2 V and power densities of up to 600 W/kg, the lead-acid

cell is an adequate, if not perfect, design for car batteries.

Anode: Cadmium

Cathode: Nickel oxyhydroxide Ni(OH)2

Electrolyte: Aqueous potassium hydroxide (KOH)

Applications: Calculators, digital cameras, pagers,

lap tops, tape recorders, flashlights, medical devices (e.g., defibrillators),

electric vehicles, space applications

The cathode is nickel-plated, woven mesh, and the anode is

a cadmium-plated net. Since the cadmium is just a coating, this cell's negative

environmental impact is often exaggerated. (Incidentally, cadmium is also used

in TV tubes, some semiconductors, and as an orange-yellow dye for plastics.)

The electrolyte, KOH, acts only as an ion conductor and does not contribute

significantly to the cell's reaction. That's why not much electrolyte is

needed, so this keeps the weight down. (NaOH is sometimes used as an

electrolyte, which doesn't conduct as well, but also doesn't tend to leak out

of the seal as much). Here are the cell reactions:

| Reaction |

V vs SHE |

| Cd + 2OH- —> Cd(OH)2

+ 2e- |

0.81 |

| NiO2 + 2H2O + 2e-

—> Ni(OH)2 + 2OH- |

0.49 |

| Cd +NiO2 + 2H2O —>

Cd(OH)2 + Ni(OH)2 |

1.30 |

Advantages include good performance in high-discharge and

low-temperature applications. They also have long shelf and use life.

Disadvantages are that they cost more than the lead-acid battery and have lower

power densities. Possibly its most well-known limitation is a memory effect,

where the cell retains the characteristics of the previous cycle.

This term refers to a temporary loss of cell capacity,

which occurs when a cell is recharged without being fully discharged. This can

cause cadmium hydroxide to passivate the electrode, or the battery to wear out.

In the former case, a few cycles of discharging and charging the cell will help

correct the problem, but may shorten the lifetime of the battery. The true

memory effect comes from experience with a certain style of NiCad in space use,

which were cycled within a few percent of discharge each time.

An important thing to know about "conditioning " a NiCd

battery is that the deep discharge spoken of is not a discharge to zero volts,

but to about 1 volt per cell.

v v

Anode:Hydrogen Gas

Cathode: Nickel oxyhydroxide

Electrolyte: Potassium hydroxide

Applications:Space satellites that require long

cycle life, over 40,000 cycles. Nickel/Hydrogen batteries have a high

self-discharge rate, something like 80% a month, which isn't a problem for

satellite applications.

The NiH2 cell is a welded pressure vessel. It

has a high specific energy, 60WH/kg, long life, can tolerate overcharge and

cell reversal, but has a low volumetric energy density, 50 WH/liter.

Here are the cell reactions:

| Location |

Reactions |

Voltage |

| Anode |

½H2 + OH- —>

H2O + e- |

0.83 |

| Cathode |

NiOOH + H2O + e- —>

Ni(OH)2 + OH- |

0.52 |

| Overall |

NiOOH + ½H2 —>

Ni(OH)2 |

1.35 |

In order to get the hydrogen gas into solution a

Teflon-bonded platinum black catalyst is used, similar to that used in fuel

cells. This platinum electrode has the added advantage that it can recombine

oxygen with hydrogen extremely fast. Since the only bad chemical reaction

during over charge is the creation of oxygen at the positive electrode this

means that the Nickel/Hydrogen battery is impossible to overcharge (though

there may be a thermal runaway problem if the excess heat isn't dissipated.) A

similar reaction keeps any damage from being done if the cell is

reverse-charged.

The battery weight for a 10kW satellite is about 350 kg,

or 770 lbs.

Anode: Rare-earth or nickel alloys with many

metals

Cathode: Nickel oxyhydroxide

Electrolyte: Potassium hydroxide

Applications: Cellular phones, camcorders,

emergency backup lighting, power tools, laptops, portable, electric

vehicles

This sealed cell is a hybrid of the NiCd and

NiH2 cells. Previously, this battery was not available for

commercial use because, although hydrogen has wonderful anodic qualities, it

requires cell pressurization. Fortunately, in the late 1960s scientists

discovered that some metal alloys (hydrides such as LiNi5 or

ZrNi2) could store hydrogen atoms, which then could participate in

reversible chemical reactions. In modern NiMH batteries, the anode consists of

many metals alloys, including V, Ti, Zr, Ni, Cr, Co, and Fe.

Except for the anode, the NiMH cell very closely resembles

the NiCd cell in construction. Even the voltage is virtually identical, at 1.2

volts, making the cells interchangeable in many applications. Here are the cell

reactions:

| Location |

Reactions |

Voltage |

| Anode |

MH + OH- —> M + H2O +

e- |

0.83 |

| Cathode |

NiOOH + H2O + e- —>

Ni(OH)2 + OH- |

0.52 |

| Overall |

NiOOH + MH —> Ni(OH)2 + M |

1.35 |

The anodes used in these cells are complex alloys

containing many metals, such as an alloy of V, Ti, Zr, Ni, Cr, Co, and

(!) Fe. The underlying chemistry of these alloys and reasons for superior

performance are not clearly understood, and the compositions are determined by

empirical testing methods.

A very interesting fact about these alloys is that some

metals absorb heat when absorbiong hydrogen, and some give off heat when

absorbing hydrogen. Both of these are bad for a battery, since we would like

the hydregen to move easily in and out without any energy transfer. The

successful alloys are all mixtures of exothermic and endothermic metals to

achieve this.

Hydrogen Storage Metals

Comparison:

| Material |

Density |

H2 Storage Capacity |

| LaNi5 |

8.3 |

0.11 g/cc |

| FeTi |

6.2 |

0.11 |

| Mg2Ni |

4.1 |

0.15 |

| Mg |

1.74 |

0.13 |

| MgNi Eutectic |

2.54 |

0.16 |

| liquid H2 |

0.07 |

0.07 |

Please notice that the density of hydrogen stored in a

metal hydride is higher than that of pure liquid hydrogen! Commercial NiMH

batteries are mostly of the rare earth-nickel type, of which LaNi5

is a representative. These alloys can store six hydrogen atoms per unit cell

such as LaNi5H6. Even misch metal nickel alloys are used

to save the cost of separation.

The electrolyte of commercial NiMH batteries is typically

6 M KOH

The NiMH cell does cost more and has half the service life

of the NiCd cell, but it also has 30% more capacity, increased power density

(theoretically 50% more, practically 25% more). The memory effect, which was at

one time thought to be absent from NiMH cells, is present if the cells are

treated just right. To avoid the memory effect fully discharge once every 30 or

so cycles. There is no clear winner between the two. The better battery depends

on what characteristics are more crucial for a specific application.

v v

Anode: Molten sodium

Cathode: Molten sulfur

Electrolyte: Solid ceramic beta alumina

(ß"-Al2O3)

Applications: Electric vehicles, aerospace

(satellites)

This cell have been studied extensively for electric

vehicles because of its inexpensive materials, high cycle life, and high

specific energy and power. Specific energies have reached levels of 150 W-h/kg

and specific powers of 200 W/kg. The half-reactions are:

| half-reaction |

V vs SHE |

| 2Na —> 2Na+ +

2e- |

|

| 3S + 2e- —>

S32- |

|

2Na + 3S —> Na2S3 2.076

V

Despite these advantages there are couple of disadvantages

serious enough that other alternatives, such as lithium-ion, nickel-metal

hydride, and lithium polymer, have emerged as the most promising solutions to

electric vehicle power. One is that the power output is very small at room

temperature. The temperature must be kept at around 350 ºC to keep the

sulfur in liquid form and to be effective in motive power applications. This is

achieved through insulation or heating through the cells own power. This lowers

the energy density.

The second problem has to do with electrolyte breakdown,

which is one of the principal causes of sodium sulfur cell failure. The

electrolyte, ceramic beta"-alumina, has several attractive characteristics. It

has all the benefits of a solid electrolyte with the added qualities of a high

ionic conductivity with a small electronic transfer, all with the added benefit

of being a solid. However, ceramic beta"-alumina also is brittle and develops

microfissures. Thus the liquid sodium and sulfur come in contact—with

explosively violent results.

Recently, some research efforts have focussed on replacing

the molten sulfur cathode with a poly(disulfide) such as

poly(ethylenedisulfide), (SSCH2CH2)n. These

cells can be discharged just above the melting temperature of Na (90 °C).

The net cell reaction becomes:

2 Na + (SSR)n=Na2SSR

where the discharge reaction involves scission of the S-S

disulfide linkage in the polymer backbone, and charge involves repolymerization

of the resulting dithiolate salt.

One of these is the sodium/metal chloride, which in

addition to beta"-alumina has a secondary electrolyte (NaAlCl4) to

conduct ions from the first electrolyte to the cathode. This is necessary

because the metal chloride is a solid.

v v

Nickel/Sodium Cells

These are specialty cells

made by one manufacturer in England, Beta Research. They have advantages for

electric vehicles. The cell runs hot, about 300 degrees C, but this isn't a

worry, since they heat themselves up during discharge. The discharge reaction

is:

| Location |

Half Reaction |

Voltage |

| Charge |

2 NaCl + Ni Z —> 2Na +NiCl2 |

|

| Discharge |

NiCl2 + 2 Na —> Ni + 2NaCl |

2.58 V |

The electrolyte on the nickel side of the alumina

separator is sodium tetracloroaluminate.NaAlCl4, which melts at 151

degrees C.. Energy density is 100 to 150 Wh/kg. These use an aluminum oxide

ceramic as a separator, similar to that of the sodium-sulfur cell. They have

the same danger of rupture of the separator, but have a unique solution to the

problem. The cell is encased in a two-wall steel thermally insulated package.

If the separator breaks the energy is confined within this package. A cell that

is broken in this way has a low resistance, so it can continue to reside in the

battery pack without causing a vehicle break-down. This double-insulated case

also prevents the cell from spilling in car crashes.

There are no

higher-voltage reactions or other side reactions, so the inventors claim that

up to the point of full charge the cell is 100% coulomb efficient–meaning

that the amp-hours you put in is exactly the same as the amp-hours you get out.

Overcharging does not damage the cell, so the battery packs are easy to keep in

balance–just overcharge the whole pack.

It seems that the cell has

no self-discharge if the batteries are cold, (solid blocks of sodium don't

migrate at room temperature) and that a pack requires about 24 hours to get to

temperature with a 230 VAC input to the pack heater.

Anode: Carbon compound, graphite

Cathode: Lithium oxide

Electrolyte:

Applications: Laptops, cellular phones, electric

vehicles

Lithium batteries that use lithium metal

have safety disadvantages when used as secondary (rechargeable) energy sources.

For this reason a series of cell chemistries have been developed using lithium

compounds instead of lithium metal. These are called generically Lithium ion

Batteries.

Cathodes consist of a a layered crystal (graphite) into

which the lithium is intercalated. Experimental cells have also used lithiated

metal oxide such as LiCoO2,

NiNi0.3Co0.7O2, LiNiO2,

LiV2O5, LiV6O13,

LiMn4O9, LiMn2O4,

LiNiO0.2CoO2.

Electrolytes are usually LiPF6, although this

has a problem with aluminum corrosion, and so alternatives are being sought.

One such is LiBF4. The electrolyte in current production batteries

is liquid, and uses an organic solvent.

Membranes are necessary to separate the electrons from the

ions. Currently the batteries in wide use have microporous polyethylene

membranes.

Intercalation (rhymes with relation—not inter-cal,

but in-tercal-ation) is a long-studied process which has finally found a

practical use. It has long been known that small ions (such as lithium, sodium,

and the other alkali metals) can fit in the interstitial spaces in a graphite

crystal. Not only that, but these metallic atoms can go farther and force the

graphitic planes apart to fit two, three, or more layers of metallic atoms

between the carbon sheets. You can imagine what a great way this is to store

lithium in a battery—the graphite is conductive, dilutes the lithium for

safety, is reasonably cheap, and does not allow dendrites or other unwanted

crystal structures to form.

v v

Manganese-Titanium (Lithium) Cells

Anode: Lithium-Titanium Oxide

Cathode: Lithium intercalated Manganese Dioxide

Electrolyte:

Applications: Watches, other ultra-low discharge

applications

This technology might be called Manganese-Titanium, but it

is just another lithium coin cell. It has "compatible" voltage – 1.5 V to

1.2 Volts, like the Lithium-Iron cell, which makes it convenient for

applications that formerly used primary coin cells. It is unusual for a lithium

based cell because it can withstand a continuous overcharge at 1.6 to 2.6 volts

without damage. Although rated for 500 full discharge cycles, it only has a 10%

a year self-discharge rate, and so is used in solar charged watches with

expected life of 15+ years with shallow discharging. The amp-hour capacity and

available current output of these cells is extremely meager. The range of

capacities from Panasonic is 0.9 to 14 mAH (yes, 0.9 milliamp hours). The

maximum continuous drain current is 0.1 to 0.5 mA.

v v

Rechargeable Alkaline

Manganese Cells

Anode: Zinc

Cathode:Manganese Dioxide

Electrolyte: Potassium Hydroxide Solution

Applications: Consumer devices

Yes, this is the familiar alkaline battery, but specially

designed to be rechargeable, and with a hot new acronym—RAM (haven't I

seen that acronym somewhere before?). In the charging process, direct-current

electrical power is used to reform the active chemicals of the battery system

to their high-energy charge state. In the case of the RAM battery, this

involves oxidation of manganese oxyhydroxide (MnOOH) in the discharged positive

electrode to manganese dioxide (MnO2), and of zinc oxide (ZnO) in the negative

electrode to metallic zinc.

Care must be taken not to overcharge to prevent

electrolysis of the KOH solution electrolyte, or to charge at voltages higher

than 1.65 V (depending on temperature) to avoid the formation of higher oxides

of manganese.

Nickel Zinc

Cells

Anode: Zinc

Cathode: Nickel oxide

Electrolyte: Potassium hydroxide

Applications:Electric vehicles, standby load

service

The

combination of nickel and zinc is very interesting because of the low cost and

low toxicity of the constituents. There have been many technical obstacles, but

a string of recent patents and a commercial start-up based on a KOH electrolyte

holds great promise for applications where light weight is an issue.

The nickel/zinc battery uses zinc as the negative

electrode and nickel hydroxide as the positive. The discharge reactions

are:

| Location |

Half Reaction |

Voltage |

| Anode |

Zn + 2OH- —> Zn(OH)2+

2e |

1.24 V |

| Cathode |

2NiOOH + 2H2O —>

2Ni(OH)2 + 2OH- |

0.49 V |

| Overall |

2NiOOH + Zn + 2H2O —>

2Ni(OH)2 + Zn(OH)2 |

1.73 |

These cells run between 1.55 and 1.65 V. Theoretical

energy density is 334 Wh/kg, or about 1.3 kg of nickel and 0.7 kg of zinc per

kilowatt-hour. The internal resistance of nickel/zinc batteries is remarkably

low, which makes this system particularly attractive for high charge and

discharge rates

Practical specific energy is around 60 Wh/kg. The

technical problems that have plagued these batteries so far are dissolution of

the zinc in the electrolyte, and uneven redepositing of the zinc during

charging. Progress in these batteries has been mostly in the improvement of the

zinc electrode. The charging is tricky because the termination voltage is a

strong function of temperature.

v v

Iron Nickel

Cells

Anode: Iron

Cathode: Nickel oxyhydroxide

Electrolyte: Potassium hydroxide

Applications:

This battery was introduced by Thomas

Edison. It is a very robust battery: it can withstand overcharge,

overdischarge, and remaining discharged for long periods of time without

damage. It is good for high depths of discharge and can have very long life

even if so treated. It has low energy density, a high self-discharge rate, and

evolves hydrogen during both charge and discharge. It is often used in backup

situations where it can be continuously charged and can last for 20 years.

The chemistry involves the movement of oxygen from one

electrode to the other: 3Fe + 8NiOOH + 4H2O=8 Ni(OH)2 +Fe3O4.

| Half Reaction |

Voltage |

| Fe + 2OH- —> Fe(OH)2

+2e- |

|

| 3Fe(OH)2 + 2OH- —>

Fe3O4 + 4H2O + 2e- |

|

The open circuit voltage of this system is

1.4 V, and the discharge voltage is about 1.2 V. The electrolyte is 30% KOH

solution, with some additives.

The ability of this system to survive

frequent cycling is due to the low solubility of the reactants in the

electrolyte. The formation of metallic iron on charge is slow because of the

low solubility of the Fe3O4, which is good and bad. It is

good because the slow formation of iron crystals preserves the electrode

morphology. It is bad because it limits the high rate performance: these cells

take a charge slowly, and give it up slowly.

v v

Iron Air

Cells

The Iron/Air is another of the air-electrode

batteries. The electrochemistry is as follows:

| Half Reaction |

Voltage |

| O2 + 2Fe +2H2O=2Fe(OH)2 |

|

| O2 +2H2O +2e=H2O2 +2(OH) |

|

These batteries require a high degree of

support, since the CO2 must be taken out of the air in order to

prevent potassium carbonates forming in the KOH electrolyte. They have been

built in large backup systems. The air electrode consists of a catalyst on a

support. For example a carbon particle substrate held together with Teflon,

coated with a silver complex catalyst. Support is provided by a silver-plated

nickel screen.

v v

Iron Silver

Cells

These have a very high energy density, and a

good cycle life. It is an alkaline battery with a KOH electrolyte, and the

working materials are silver oxide and metallic iron. The high cost of these

batteries have long been a problem, but an ounce of silver in a cell phone

battery would probably cost less than an ounce of the rare earths now used in

some NiMH batteries.

v v

Redox (Liquid

Electrode) Cells

These consist of a semipermeable membrane having different

liquids on either side. The membrane permits ion flow but prevents mixing of

the liquids. Electrical contact is made through inert conductors in the

liquids. As the ions flow across the membrane an electric current is induced in

the conductors. These cells and batteries have two ways of recharging. The

first is the traditional way of running current backwards. The other is

replacing the liquids, which can be recharged in another cell. A small cell can

also be used to charge a great quantity of liquid, which is stored outside the

cells. This is an interesting way to store energy for alternative energy

sources that are unreliable, such as solar, wind, and tide. These batteries

have low volumetric efficiency, but are reliable and very long lived.

Electrochemical systems that can be used are

FeCl3 (cathode) and TiCl3 or CrCl2

(anode). Vanadium redox cells: A particularly interesting cell uses vanadium

oxides of different oxidation states as the anode and cathode. These solutions

will not be spoiled if the membrane leaks, since the mixture can be charged as

either reducing or oxidizing components.

Unlike batteries, which store energy chemically,

capacitors store energy as an electrostatic field. Typically, a battery is

known for storing a lot of energy and little power; a capacitor can provide

large amounts of power, but low amounts of energy. A capacitor is made of two

conducting plates and an insulator called the dielectric, which conducts

ionically, but not electrically. In a capacitor,

Ecap = qV = ½CV2

where the capacitance, C, is directly proportional to the

surface area of the plates and inversely proportional to the distance between

them.

So in other words, as the plate surface area increases and

the distance between the plates decreases, the energy you can store in a

capacitor increases. Normal every-day capacitors have capacity on the orders of

millifarads per cubic foot. Aluminum electrolytics are about a farad per cubic

foot. But for useful energy storage we need farads per cubic inch. That is

where supercapacitors come in.

First let's see how clever we can get to obtain a big

surface area in a small volume. Imagine a polymer foam cleaning sponge. It has

a tremendous amount of surface area in a small area because of all the

crenulations (OK, nooks and crannies). Now, put it in a furnace, excluding the

oxygen and bake it until only the carbon is left. You now have a conductive

carbon surface with an incredible surface area in a small volume.

But to get a high capacitance there has to be two plates.

You can't just go in there and create complimentary surface as the other

electrode—or can you? Yes, just fill it with a conductive liquid (e.g., an

aqueous acid or salt solution). The last thing you need is an ultra-thin

insulator on the carbon. Ultra thin to get high capacitance, and insulator so

the carbon and the liquid don't short out. This is also easy, you can

electrochemically deposit an insulator on the carbon surface (or

electrochemically deposit something that could be turned into an insulator upon

baking).

Now attach one electrode to the carbon, one to the liquid,

and you can have a capacitor that can have Farads of capacitance per cubic

inch. Very nice.

Most practical supercapacitors have low voltage (2 to 5

V—remember that insulator is ultra-thin and so can break down at low

voltages), which is a problem for energy storage, since the stored energy is

proportional to the square of the voltage. Also, conduction through an ionic

liquid is slow, so these capacitors cannot be discharged quickly compared with

standard capacitors, but can be discharged very quickly compared to

batteries!

Typical numbers for capacitors and batteries are given

below:

| device |

volumetric

energy

density

Wh/L |

power

density

W/L |

number of

charge/discharge

cycles |

discharge

time

s |

| batteries |

50-250 |

150 |

1 - 103 |

> 1000 |

| capacitors |

0.05 - 5 |

105 - 108 |

105 - 106 |

<1 |

Supercapacitors have several advantages over batteries:

they can experience virtually indefinite number of cycles (charging and

discharging), they are maintenance free, they work well in high-rate discharge,

they recharge quickly, and they have no negative environmental impact.

v v

- Berndt, D. Maintenance-Free Batteries. New

York:: John Wiley & Sons, 1997.

- Crompton, T. R. Battery Reference Book. London:

Butterworth–Heinemann, 1990.

- Linden, D. (Ed), Handbook of Batteries.

Maidenhead: McGraw–Hill, 1995.

- Linford, R. G. (Ed), Electrochemical Science and

Technology of Polymers. New York: Elsevier, 1990.

- Ovshinsky, S. R., Fetcenko, M. A., and Ross, J. A. "A

Nickel Metal Hydride Battery for Electric Vehicles", Science 260: 1993,

176–81.

- Rechargeable Batteries Applications Handbook.

Stoneham: Butterworth–Heinemann, 1992.

- Wells, A. F. Structural Inorganic Chemistry.

Oxford: Clarendon Press, 1975.

v

v

|