| April 25, 2024 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lead Acid Battery Charging Basics and ChargersSealed lead acid SLA battery charging and flooded lead acid battery charging technologies |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SLA Battery Charging Table of Contents

SLA ChargingBasicsLead acid batteries have come a long way. They have an incredible number of man-hours in research, science, and manufacturing technology. The high voltage, robustness, infrastructure and low cost will make sure they stick around for a long time. Weight We have visited at least 10 factories in China. One interesting thing that I learned is that you can judge a sealed lead acid battery by its weight. They said "If you want a cheaper battery, no problem, we will just use thinner plates and less lead." Of course the thinner plates will fail faster and give less lifetime. That is the trade-off. All the battery factories in China run off the same basic profit margin, so if the battery is significantly cheaper, now you know why. You can judge the quality of a sealed lead acid battery by its weight. Coulometric Efficiency. This is the efficiency of battery charging based solely on how many electrons you push in. If you compare watts in to watts out you have to take into account that the battery charging voltage is higher than the battery discharging voltage. The coulometric charging efficiency of flooded lead acid batteries is typically 70%, meaning that you must put 142 amp hours into the battery for every 100 amp hours you get out. This varies somewhat depending on the temperature, speed of charge, and battery type. Sealed lead acid batteries are higher in charge efficiency, depending on the bulk charge voltage it can be higher than 95%. Minimum voltageAnything above 2.15 volts per cell will charge a lead acid battery, this is the voltage of the basic chemistry. This also means than nothing below 2.15 volts per cell will do any charging (12.9V for a "12V" battery) However, most of the time a higher voltage than this is used because the battery will accept higher currents, enabling the charging reaction to proceed at a higher rate. Charging at the minimum voltage will take a long long time--over 200 hours. At 2.25V per cell (13.5) it would take 85-120 hours to fully charge. As you increase the voltage to get faster charging, the voltage to avoid is the gassing voltage, which limits how high the voltage can go before undesirable chemical reactions take place. Charging voltages range between 2.15V per cell (12.9V for a "12V" 6 cell battery) and 2.35V per cell (14.1V for a "12V" 6 cell battery). These voltages can be applied to a fully charged battery without overcharging or damage, since they are below the "gassing" voltage, and cannot break down the electrolyte. If the battery is not yet fully charged you can use much higher voltages without damage because the charging reaction takes precedence over any over-charge chemical reactions until the battery is fully charged. This is why a battery charger can operate at 14.4 to 15 volts during the bulk-charge phase of the charge cycle. Using modern precision chargers allows both a fast charge and safe floating voltages, allowing them to be left on the battery continuously. 6V batteries need to stay below 7.1V to avoid gassing, and typical charge voltages are 6.9V (float) to 7.5V (bulk charge). The basic lead acid battery is ancient and a lot of different charge methods have been used. In the old days, when charging voltage was difficult to regulate accurately, flooded lead acid batteries were important because the water can be replaced. The lead acid chemistry is fairly tolerant of overcharging, which allows marketing organizations to get to extremely cheap chargers, even sealed lead acid batteries can recycle the gasses produced to prevent damage to the battery as long as the charge rate is slow. We offer a range of chargers from inexpensive to very sophisticated, depending on the requirements of the customer, but all of the chargers we sell off-the-shelf are highly regulated sophisticated chargers that cannot overcharge the battery. Cyclic versus Standby charging.Some lead acid batteries are used in a standby condition in which they are rarely cycled, but kept constantly on charge. These batteries can be very long lived if they are charged at a float voltage of 2.25 to 2.3 volts/cell (at 25 degrees C) (13.5V to 13.8V for a 12V battery). This low voltage is to prevent the battery from losing water during long float charging. Those batteries that are used in deep discharge cycling mode can be charged up to 2.45 volts/cell (14.7V for a 12V battery) to get the highest charge rate, as long as the voltage is dropped to the float voltage when the charge is complete. Voltage table for cyclic use charging. The higher voltages (above the gassing voltage) should only be used on flooded batteries that can have the water replaced:

Voltage table for standby use charging:

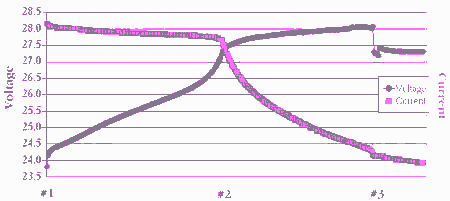

* Note that a fully discharged battery has very little sulfuric acid in solution, and since it is mostly water it will freeze solid at about 0°C, a fully charged battery has concentrated sulfuric acid as the electroylte and freezes about -72°C. This is why a discharged battery won't take a charge in sub-freezing weather. Overnight ChargingUnregulated Transformer-Based ChargersThese are the absolute cheapest chargers around. They used to be very common when semiconductors were expensive and regulation was complicated. They consist of a wall-mount transformer and a diode. The transformer is designed to deliver 13 to 14 volts over a reasonable current range. The biggest problem with this approach is that when the current tapers off, the voltage raises to 15, 16, 17, even 18 volts. These high voltages can force electrolysis of the water in the battery's electrolyte. These unregulated chargers must not be left to trickle or float-charge a battery, they should be disconnected when the battery is fully charged. This is not a problem with flooded batteries as long as you check the water periodically and refresh it. Sealed lead acid batteries can recycle the generated gasses as long as they are being overcharged at less than C/3. However, PowerStream's testing has shown that leaving the battery to be overcharged even at C/10 (a 10 hour charge rate) will corrode the plates if left on for weeks at a time. The transformer is so designed as to limit the current while the battery is in absorption mode. As the battery voltage rises the current decreases to top off the battery. Because the transformer is used to control the current and voltage these chargers are typically heavy and get hot. Note to our OEM customers: even though we support our OEM customers with unregulated transformer chargers to help them stay cost competitive, many of our new customers come to PowerStream because someone else sold them an unregulated charger without explaining the trade-offs, and the end-user complaints forced them to look for a better charger. Most of the time the complaints come from commercial customers rather than consumer customers. We prefer to offer the inexpensive, precise, regulated chargers that use switchmode power conversion. Taper chargersAnother inexpensive way to charge a sealed lead acid battery battery is called a taper charge. Either constant voltage or constant current is applied to the battery through a combination of transformer, diode, and resistance. The unregulated chargers mentioned above are taper chargers. A better, and not very expensive, alternative is a regulated taper charger. These don't let the voltage climb higher than the trickle charge voltage, so they can be also be used to maintain a battery. They won't damage the battery if left on charge too long (even when left on the battery permanently), and they don't change their charging characteristics if the line voltage should change. Regulated taper chargers are very useful when you need a 12V or 24V battery backup. A taper charger in parallel with the battery, in parallel with the load makes an effective battery back-up. You should take care to ensure that the taper charger is designed to give continuous current equal to the load plus some left over for battery charging. It is also important that the current limit of the taper charger is the voltage-cut-back method, and not the hiccough method or other PWM methods. An example of suitable switching type regulated taper chargers that can be used in battery back up applications is here There are two ways to make a regulated charger. The first is to use a transformer and a linear voltage regulation circuit. This has the disadvantages of weight and heat, but it is still inexpensive. The second uses a modern switching power supply in a wall mount or desk mount package. These low-power high-frequency switchers are surprisingly cheap, efficient, and small. They are rapidly taking over the overnight charging requirement in consumer equipment. An example of a switching-type taper charger is here . Constant current chargersA more sophisticated and not much more expensive charger uses an electric circuit to control the charging current. This method is useful for recovering batteries that have suffered from extensive storage without charging, but is capable of overcharging a battery if there is not some voltage limiting function, usually from the transformer. For this reason these chargers are limited to slow charging. This charger will switch to a constant-current mode when desulfating is necessary, and to a multistage precision charger at other times. Constant Voltage Chargers (Taper plus current limit)A circuit that is set for the maximum allowable charge voltage, but has a current limit to control the initial absorption current can produce a very nice charger. This type of charger can both charge at a reasonable rate and maintain the battery at full charge without damage. Not all constant voltage chargers are made equal, however, because the maximum voltage is a function of temperature. A temperature compensated charger is a little more expensive, and should be used where the temperature varies significantly from room temperature and the battery is on float permanently. The large chargers at An example of a switching type taper charger is here are constant voltage chargers. Pulse chargersI have a 3-inch binder full of pulse charging patents, the earliest from around 1900, which used a motor to spin electrodes to do the necessary pulsing. The early patents were trying to remove the bubbles from the plates of flooded cells that were being overcharged due to total lack of voltage control of chargers of that era. We have designed and experimented with pulse chargers, and haven't found any advantage over a modern desulfating charger. Some patents show a different crystal structure formed when pulse charging versus DC charging, which is interesting, but not necessarily relevant, particularly for modern absorbed-glass-matt batteries. Fast ChargersFast chargers are higher power units, designed to charge in less than 4 hours. These chargers require active charge termination and often have advanced features such as battery test, bad battery recovery, and automatic maintenance. It is safe to fast-charge all lead acid batteries with modern fast charge algorithms. Typical Charging curves for PowerStream quick chargers. This charger starts at 8 amps and maintains a near-constant current until nearly full. This is the fundamental algorithm of the PowerStream quick chargers for lead acid batteries. The curve shown is for a 24 volt (12 cell) battery charger, but the curve is similar at other voltages. The timing of the phase-switching depends on the size of the battery you are using. At point #1 the battery is tested. If the battery is bad a rejuvenation algorithm is started. If the battery is good the charger goes into constant current mode until the voltage reaches 2.3 volts/cell. This allows the battery to be charged at the highest current available from the charger without overloading the charger. Then at point #2 the highest safe voltage is reached and the charger goes into constant voltage mode until the current drops to about 10% of the initial value, indicating a nominally full charge. When this is detected, at point #3 the charger goes into float charging mode at about 2.3 volts /cell to complete the fill and to maintain the battery. At this voltage the battery is safe from overcharging, and also safe from sulfating, so it is also called the maintenance mode. Examples of fast chargers are shown at /scooter.htm The exact details of current and time depend on the charger size and the battery size. Maintenance, keeper or 'tender' ChargersAny multistage charger that has a "float" mode can be used to maintain batteries during the 'off-season.' Particularly useful are the small, inexpensive switchmode chargers that consume very little excess power , or the small low-power chargers that can automatically desulfate lead acid batteries. I use these to keep my motorcycle and lawn mower charged in the winter, and my car charged in the summer. High Power Battery ChargersBig battery applications such as fork lifts, floats, and golf carts have traditionally used what is called rectifiers to charge their batteries because of the relatively low price for large power levels. The "rectifier" consists of a transformer and diode bridge array and possibly some control or readout electronics. These work well, but the voltage might not be well regulated, which is made up for by using flooded batteries where the water can be topped off. These chargers are not appropriate for sealed lead acid batteries because their water cannot be replaced. And modern switchmode technology has made it possible to make inexpensive well regulated lead acid battery chargers such as this 8000 watt 48V charger. DC Input Battery ChargersThere are several reasons to charge sealed lead acid batteries from DC power sources. Solar panels require a special type of charger called a solar charge controller. These are able to take whatever power is available from the solar panels, condition that power and transfer it to the battery. These chargers are specially designed to deal with the uncertainty of the available input power.  In other cases you might have a 24 volt source and want to charge a 12 volt battery, charge a 24 volt wheel chair from a 12 volt source, or other combinations of DC input battery charging. These are DC/DC converters with current limiting voltage fold-back and often multi-stage charging. Custom design and manufacture of state-of-the-art battery chargers, UPS, and power supplies for OEMs in a hurry! |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

| |||||||||